Black TPR Scrap

Black TPR Scrap Specification

- Material

- Thermoplastic Rubber (TPR)

- Packaging Type

- Loose, Jumbo Bag, or as per buyer requirement

- Thickness

- Varies; originally from various sources

- Hardness

- 60-80 Shore A (approximate for TPR)

- Usage & Applications

- Recycling, Shoe Soles, Automotive, Injection Molding, Compounding

- Form

- Scrap

- Type

- Industrial Plastic Scrap

- Material Feature

- Flexible, Recyclable, Good Resistance to Wear

- Density

- 1.25 Gram per cubic centimeter(g/cm3)

- Grade

- Recycled / Industrial Grade

- Tensile Strength

- 10-20 MPa (typical range for TPR scrap)

- Melting Point

- 150-180C

- Weight

- Variable (supplied per lot or as per buyer requirement)

- Color

- Black

Black TPR Scrap Trade Information

- Minimum Order Quantity

- 1 Ton

- Supply Ability

- 400 Tons Per Month

- Delivery Time

- 1 Days

About Black TPR Scrap

Versatile Features and Applications of Black TPR Scrap

Black TPR Scrap is precisely processed by advanced machinery to ensure uniformity and consistency. Its machine-friendly nature facilitates easy melt-processing, extrusion, and re-molding, making it a top choice for manufacturers. Widely used in commercial applications such as the recycling industry, automotive components, shoe soles, and injection molding, this recycled rubber material offers both durability and flexibility. Its good resistance to wear and adaptable properties boost its demand in varied industrial and commercial sectors.

Supply Ability and Market Reach for Black TPR Scrap

Our supply process is streamlined for efficiencyPurchase Orders are processed promptly, backed by robust Stock levels. Secure Shipping within India and to international destinations ensures your order arrives safely and on time. Express Shipping options are available for urgent requirements. With a substantial Supply Ability, we cater to major domestic regions and leading export markets, supporting a diverse clientele ranging from local manufacturers to global distributors and traders. Quality is consistently maintained across all shipments.

FAQs of Black TPR Scrap:

Q: How is Black TPR Scrap processed and prepared for market?

A: Black TPR Scrap is collected, cleaned, and processed to remove major contaminants and metals. It is then granulated, chopped, or agglomerated to suit various industrial applications, ensuring it is ready for melt-processing, extrusion, or re-molding.Q: What are the primary applications for Black TPR Scrap?

A: Black TPR Scrap is mainly used in recycling, production of automotive parts, shoe soles, compounding, and injection molding, offering flexibility and durability in end products.Q: Where should Black TPR Scrap be stored to maintain quality?

A: Black TPR Scrap should be housed in a dry, shaded area to minimize moisture absorption and maintain its flexible, high-purity characteristics.Q: When can I expect delivery after placing a Purchase Order?

A: Delivery times vary based on location and shipping method chosen. Secure Shipping and Express Shipping options ensure prompt and reliable delivery following order confirmation.Q: What are the benefits of using recycled TPR scrap in manufacturing?

A: Utilizing recycled TPR scrap reduces material costs, supports environmental sustainability, and delivers strong mechanical properties like good wear resistance and flexibility.Q: How does the supplier ensure the quality and purity of the scrap material?

A: The supplier rigorously inspects and processes the scrap to eliminate most visible contaminants and metals, ensuring a high-purity, low-contaminant product suitable for industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

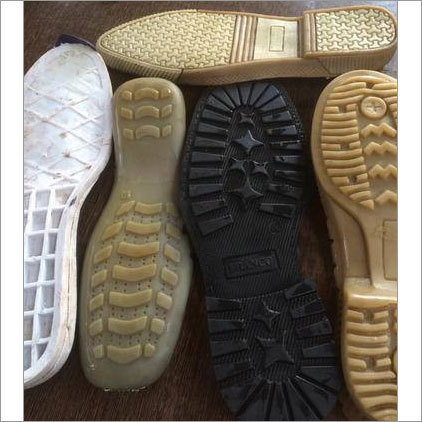

More Products in TPR Shoe Soles Scrap Category

Mixed Color TPR Sole Scrap

Price Range 30.00 - 40.00 INR / Kilograms

Minimum Order Quantity : 1 Ton

Material : Thermoplastic Rubber (TPR)

Grade : Industrial / Recycled

Weight : Variable (bulk or packaged)

Packaging Type : Bags or loose

Moulding Grade TPR Scrap

Price Range 30.00 - 40.00 INR / Kilograms

Minimum Order Quantity : 1 Ton

Material : Thermoplastic Rubber (TPR)

Grade : Moulding Grade

Weight : Variable, supplied in bulk

Packaging Type : Loose or bulk bags

Mix TPR Scrap

Price Range 30.00 - 40.00 INR / Kilograms

Minimum Order Quantity : 1 Ton

Material : Thermoplastic Rubber (TPR)

Grade : Industrial/Recycled

Weight : Customized or as per buyer requirement

Packaging Type : Bags or bulk packaging

TPR Sole Scrap

Price Range 30.00 - 40.00 INR / Kilograms

Minimum Order Quantity : 1 Ton

Material : Thermoplastic Rubber (TPR)

Grade : Industrial scrap grade

Weight : Variable, available in bulk

Packaging Type : Loose or bulk bags

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry